1. Disosal diaper waste recycling technology

With the aging of Japan's population, the amount of disposable adult diapers is increasing. Currently, most of the used disposable diapers are incinerated. However, due to the low flammability of disposable diapers, the cost of auxiliary fuel and incineration residues is increasing.

In addition, incineration of disposable diapers tends to accelerate the deterioration of incinerators due to the high heat of combustion, increasing repair costs and shortening the life of incinerators. For this reason, the Ministry of Environment has issued guidelines to promote the recycling of disposable diapers.

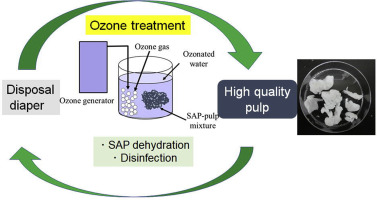

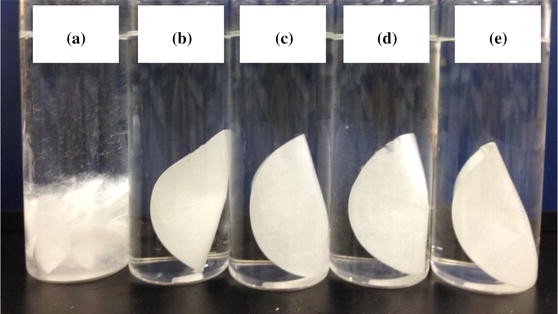

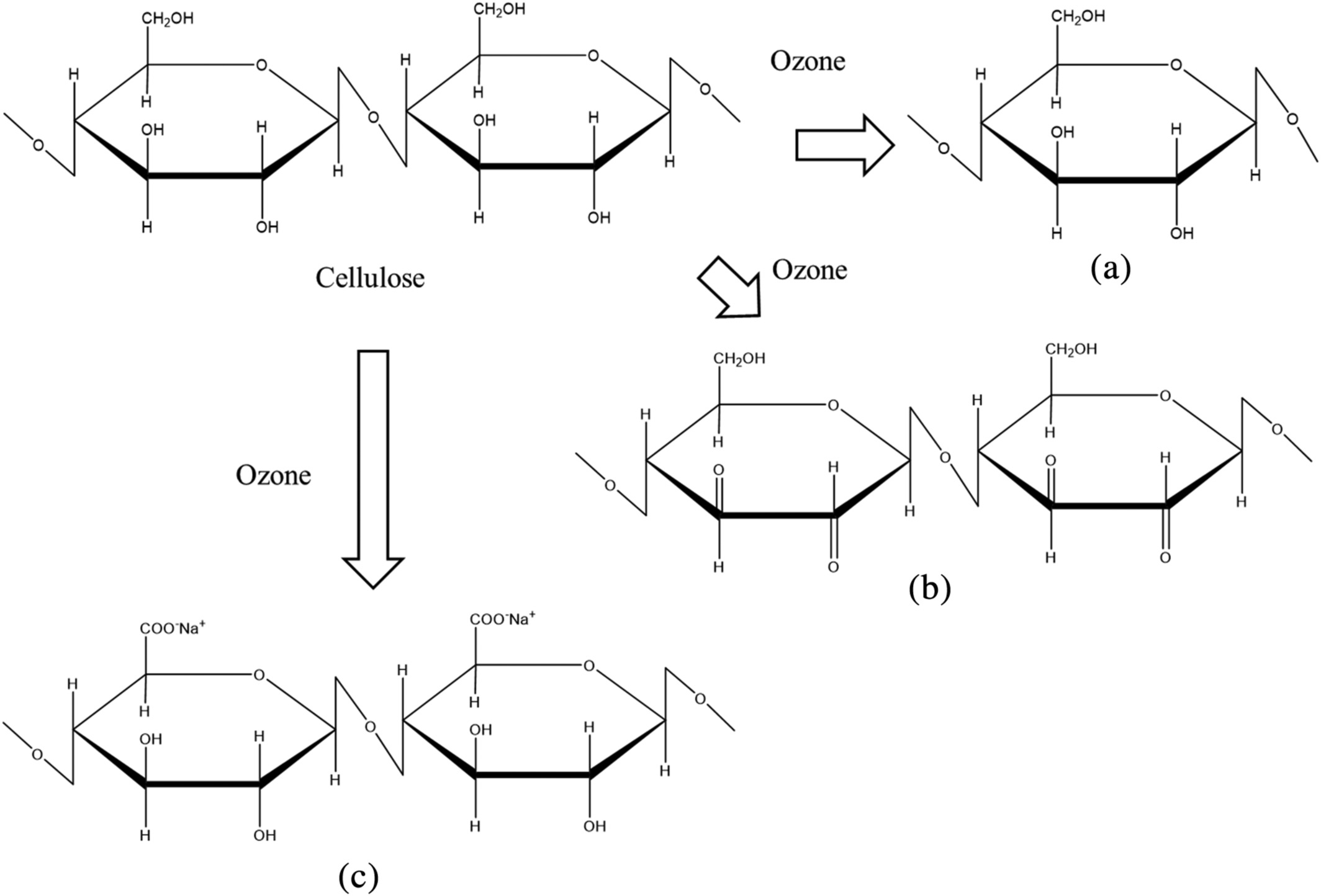

In this study, we established a new technology for recycling paper diapers using ozone. As a result, we were able to recover the pulp contained in used diapers, which was difficult to do in the past. This technology has made it possible to reuse the pulp in disposable diapers. In addition, a demonstration test of this technology is underway in Shibushi City, Kagoshima Prefecture. In addition, full-scale implementation is planned to begin in fiscal 2023, when a project to produce disposable diapers using the recovered pulp is scheduled to be launched.

Related paper

・Journal of cleaner production 276, 123350 (2020), DOI: https://doi.org/10.1016/j.jclepro.2020.123350.

2. Development of biodegradable materials using cellulose

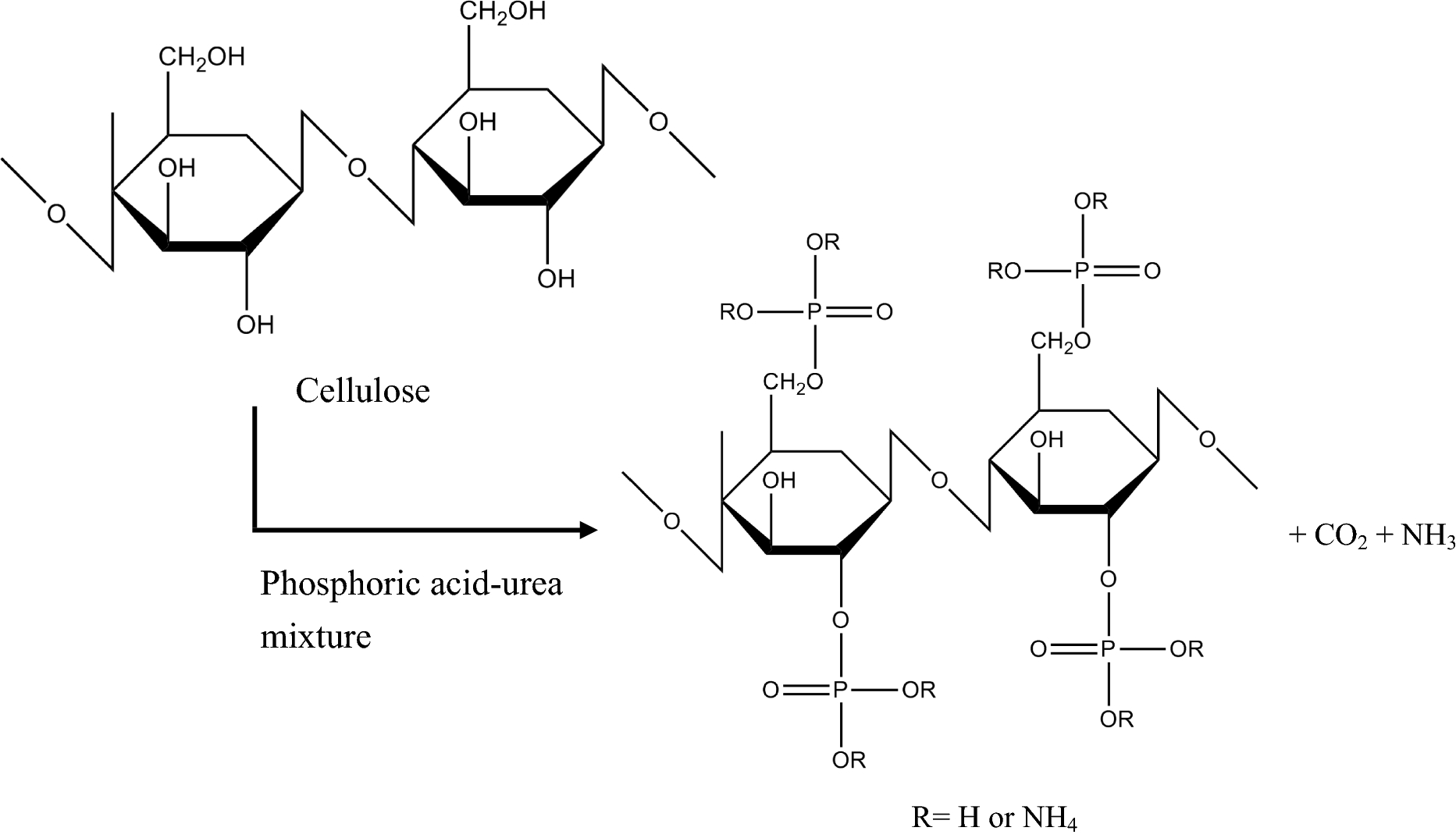

This research is about biodegradable materials for paper made with cellulose from a wood component.

Then, the paper is required as a biodegradable materilas, and is focused on an alternative materilas of plastic. However, the disadvantage of paper is the wet paper strength (the paper strength wetted by water). In addition, the control of biodegradability is also important. For example, when paper is used as a mulch film for agriculture, if it decomposes before the crop is grown, the mulch film becomes useless.

Therefore, we are studying the development of paper materials with both microbial control of degradation and wet paper strength using a simple method with phosphoric acid and urea.

Related paper

・ Cellulose, 26, 5105-5116 (2019) DOI: https://doi.org/10.1007/s10570-019-02423-y

3. Development of functional paper with ionic liquids

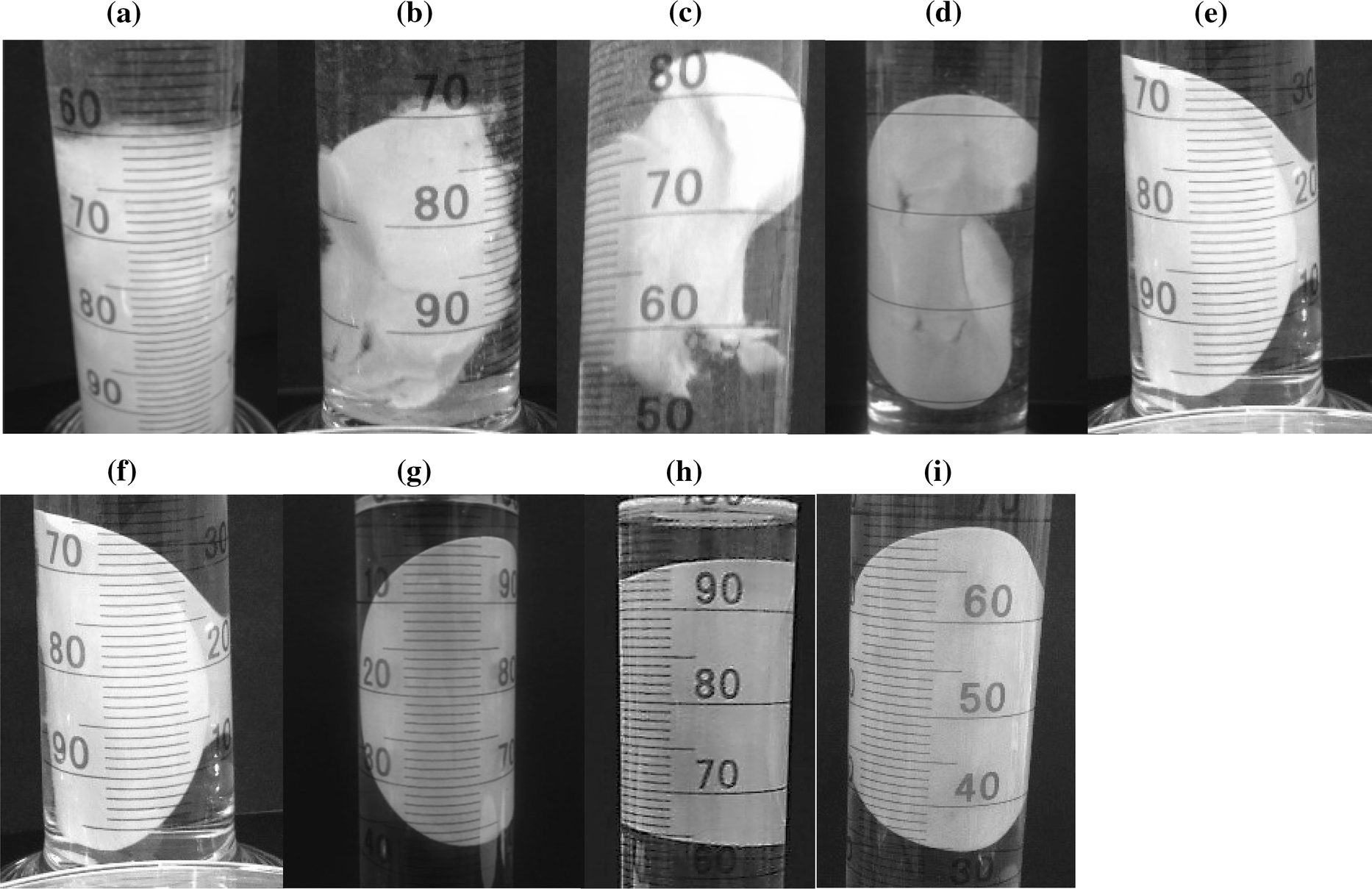

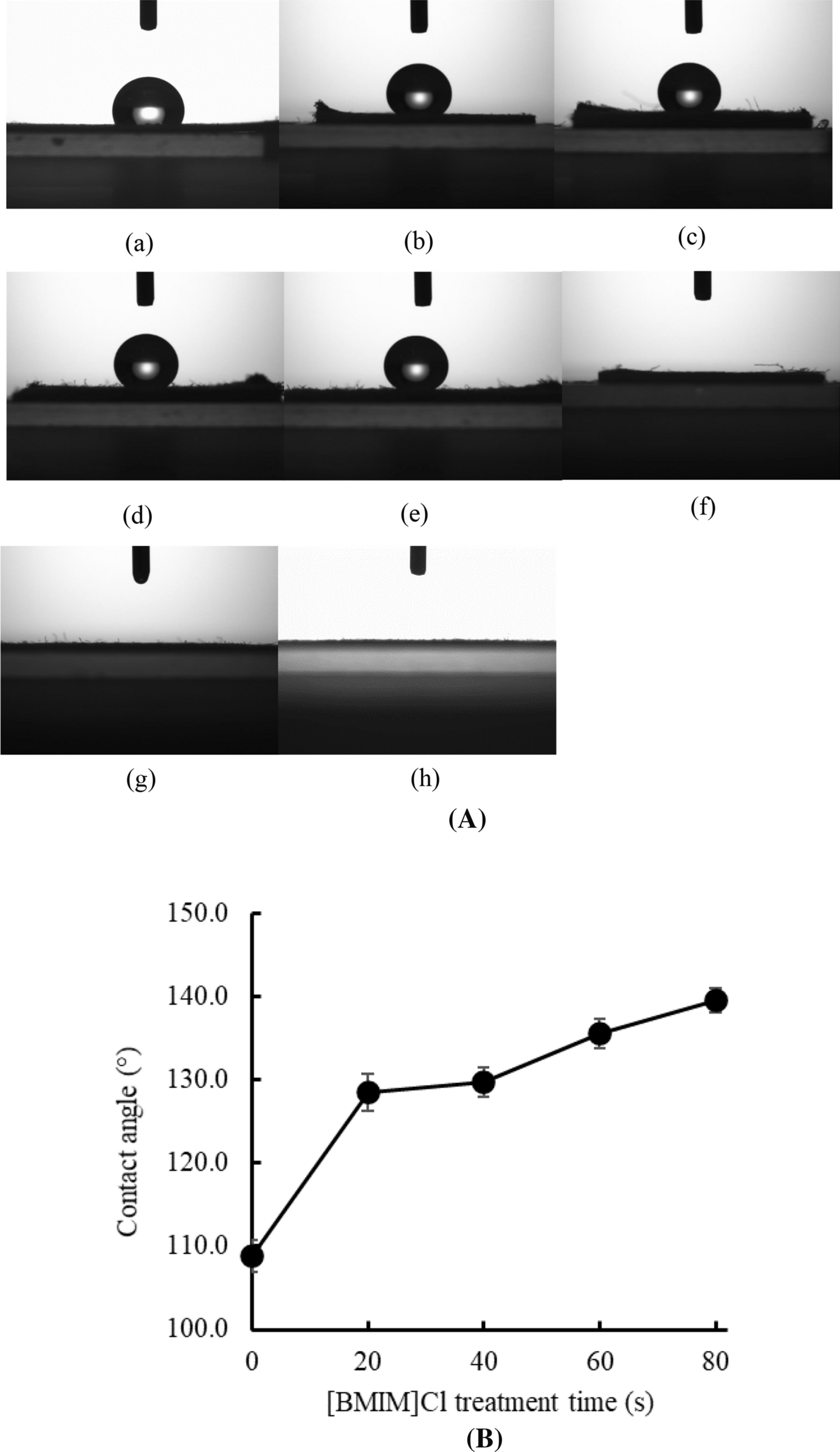

We have attempted to make wet strength paper by partially dissolving the cellulose in the paper with an ionic liquid (a new solvent that can dissolve cellulose). The wet strength reagents are used to maintain the strength of paper that is wetted by water. For example, these reagents are applied to water-resistant corrugated board, wrapping paper, paper towels, and tissue paper.

Polyamide-polyamine-epichlorohydrin (PAE) resin is used as a wet strength resin. However, due to the high toxicity of its by-product, alternative resins have recently become necessary for environmental reasons.

In this study, we used ionic liquids to improve the wet strength of paper. By ionic liquid treatment, the high wet strength was obtained, and then the paper with high wet strength was composed entirely of cellulose.

The paper treated with ionic liquid can be used in aqueous environments. By adding activated carbon or catalyst to the paper, it is expected to be used as water purification paper or catalyst paper that can be used in aqueous environments.

Paper made from pulp treated with ionic liquids has been shown to improve not only tensile strength, but also specific surface area, polyethylene glycol adsorption rate, and moisture retention rate.

Related paper

・Cellulose 27, 8317-8327 (2020), DOI: 10.1007/s10570-020-03303-6.

・Cellulose, 24(8), 3469-3477 (2017). DOI: 10.1007/s10570-017-1340-8.

・Cellulose, 32, 4341-4344 (2025). DOI: https://doi.org/10.1007/s10570-025-06512-z

4. Utilization of palm fiber (joint research with a university in Indonesia)

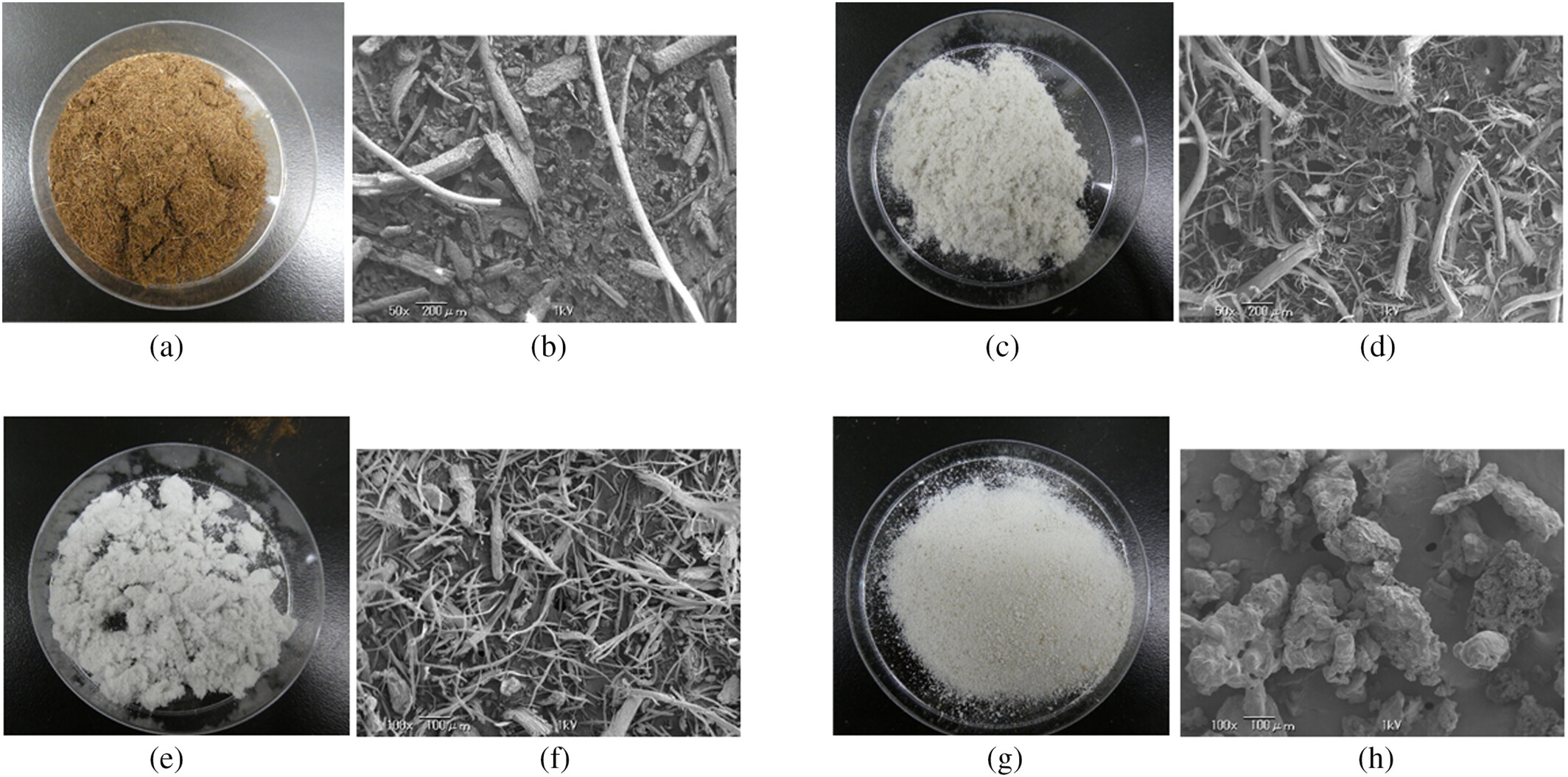

This study is an international collaboration on the effective use of waste generated by the palm oil industry in Indonesia.

Palm oil accounts for 12% of Indonesia's export industry. As a result, a large amount of waste from the palm oil industry is produced, and then the palm fiber accounts for 22-24%. Palm fiber contains 50% cellulose, and the cellulose contained in the waste palm fiber is tried to be used as the cellulose products.

In this study, we prepared carboxymethyl cellulose and use it in the food field. By using ozone treatment, we were able to control the properties of carboxymethyl cellulose and add value to it.

Related paper

・Journal of applied polymer science 138, e54228 (2023), DOI: https://doi.org/10.1002/app.54228

・Journal of applied polymer science 138, e49610 (2021), DOI: https://doi.org/10.1002/app.49610

5. Intelligent functional paper

Smart materials express functions in response to the external environment. We are applying the cenceput of intelligent material to paper and nonwoven. This will make it possible to create paper and nonwovens with detection in the external environment, and then the paper and nonwoven sheet with novel function can be produced.

We prepared the paper that responds to components in the body and the temperature change. The intelligent function that releases odors in response to external changes was also prepared.

Related paper

・ Journal of Applied Polymer Science, 134(9) , 44530 (2017) DOI: https://doi.org/10.1002/app.44530.

・Chemical Engineering Journal, 245, 17-23(2014). DOI: https://doi.org/10.1016/j.cej.2014.02.019

・Journal of Applied Polymer Science, 129, 2139-2144 (2013). DOI: https://doi.org/10.1002/app.38941

・Journal of Applied Polymer Science, 127, 1725-1729 (2013). DOI: https://doi.org/10.1002/app.37902.

・ Journal of Materials Science, 45, 1343-1349 (2010) DOI: https://doi.org/10.1007/s10853-009-4088-1.

・Journal of Materials Science, 44, 992-997 (2009).DOI: https://doi.org/10.1007/s10853-008-3220-y

・Journal of Materials Science, 43, 1486-1491 (2008). DOI: https://doi.org/10.1007/s10853-007-2341-z

・ Journal of Materials Science, 40, 1987-1991 (2005).DOI: https://doi.org/10.1007/s10853-005-1221-7

6. Paper sludge recycling

The pulp component of paper sludge discharged from the pulp and paper industry is incinerated, and the remaining inorganic materials are disposed of in landfills. Research on paper sludge has focused mainly on the reuse of inorganic materials because it is difficult to separate the pulp and inorganic materials from the paper sludge.

In this study, pulp and inorganic components are separated and recovered using ionic liquids. Ionic liquids have been reported to dissolve pulp components, and the use of ionic liquids can selectively dissolve only the pulp content, thereby enabling the separation and recovery of inorganic and pulp components.

Related paper

・ Journal of Material Cycles and Waste Management, SPECIAL FEATURE: ORIGINAL

ARTICLE AGRO' 2014,18(2), 215-221, (2016). DOI :https://doi.org/10.1007/s10163-015-0391-x

・ Chemical Engineering Journal, 173, 129-134 (2011) DOI:https://doi.org/10.1016/j.cej.2011.07.048

7. Development of functional paper using interfacial polymerization reaction

In this research, we try to functionalize the surface of paper and nonwovens, which are sheet-like materials, with the keyword "control of nano-interface on paper surface".

The basic concept is to simultaneously prepare and fix the functional materials on the surface of paper using the nano-interface region formed on the paper surface. We are trying to create sheet-like materials with different functions.

We are attempting to prepare polymer films directly on the surface of sheet materials such as paper and nonwovens using an interfacial polymerization reaction. The polymer films with microcapsule, fiber and porous shapes have been prepared on the paper surface.

Since it is possible to synthesize polymer films with different morphologies, it is expected that sheet materials will be developed according to the characteristics of their morphologies.

In this study, we studied about the basic experiments to elucidate the mechanism by which this morphology is changed. We also investigated the insect repellent paper with sustained release effect and adhesive paper that does not require release paper by using this method.

Related paper

・Ichiura H., Kawahara U., “Polyamide film containing a molecularly imprinted

polymer prepared on a paper surface by interfacial polymerization and its

selective adsorption of benzalkonium chloride”, Journal of applied polymer

science, e55077 (2023). DOI: https://doi.org/10.1002/app.55077.

・Chemosphere, 256, 127143 (2020). https://doi.org/10.1016/j.chemosphere.2020.127143

・ Industrial & Engineering Chemistry Research, 55(4), 961-966 (2016).

DOI: https://doi.org/10.1021/acs.iecr.5b04548

・ Polymer bulletin, 72, 2621-2632 (2015). DOI: https://doi.org/10.1007/s00289-015-1426-0

・ Industrial & Engineering Chemistry Research, 52, 9137-9144 (2013).

DOI: https://doi.org/10.1021/ie401082a

・Journal of Applied Polymer Science, 124, 242-247 (2012). DOI: https://doi.org/10.1002/app.33900

・Journal of Materials Science, 41, 7019-7024 (2006).DOI: https://doi.org/10.1007/s10853-006-0789-x